Seal rings are essential components in various applications, providing a barrier to prevent leaks and maintain pressure. Among the different materials available, silicone seal rings are popular due to their unique properties. This guide will compare silicone seal rings with other materials, highlighting their advantages and disadvantages.

Introduction to Silicone Seal Rings

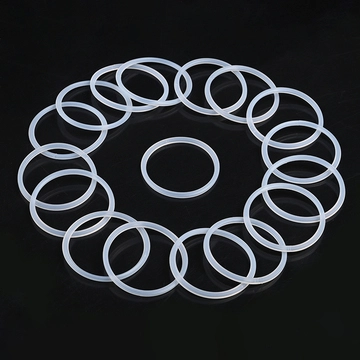

Silicone seal rings are made from silicone seal ring rubber, a versatile material known for its flexibility and durability. Silicone can withstand extreme temperatures, making it suitable for various applications. These seal rings are commonly used in automotive, aerospace, and household products. Their resistance to UV light and ozone also contributes to their longevity.

Advantages of Silicone Seal Rings

One of the primary advantages of silicone seal rings is their temperature resistance. They can operate effectively in a wide temperature range, typically from -60°C to 200°C. This makes them ideal for applications that experience extreme heat or cold. Additionally, silicone seal rings are resistant to aging and degradation, ensuring a longer lifespan compared to other materials.

Disadvantages of Silicone Seal Rings

Despite their many advantages, silicone seal rings have some drawbacks. They may not be suitable for applications involving petroleum-based fluids, as silicone can swell and lose its sealing properties. Furthermore, silicone is generally more expensive than other materials, which can be a consideration for budget-conscious projects.

Comparing with Nitrile Rubber Seal Rings

Nitrile rubber, also known as Buna-N, is another common material used for seal rings. Nitrile seal rings are known for their excellent resistance to oils and fuels, making them suitable for automotive and industrial applications. However, they have a narrower temperature range compared to silicone, typically from -40°C to 100°C.

Advantages of Nitrile Rubber Seal Rings

Nitrile rubber seal rings excel in applications involving petroleum-based fluids. They provide a reliable seal in environments where silicone may fail. Additionally, nitrile is generally more affordable than silicone, making it a popular choice for many manufacturers.

Disadvantages of Nitrile Rubber Seal Rings

The primary disadvantage of nitrile rubber seal rings is their limited temperature range. They can become brittle in extreme cold and may degrade when exposed to high temperatures. Nitrile also has a shorter lifespan compared to silicone, especially in harsh environments.

Comparing with EPDM Seal Rings

Ethylene Propylene Diene Monomer (EPDM) is another material used for seal rings. EPDM seal rings are known for their excellent resistance to weathering, ozone, and UV light. They are commonly used in outdoor applications, such as roofing and automotive weather seals.

Advantages of EPDM Seal Rings

EPDM seal rings offer good resistance to environmental factors, making them suitable for outdoor use. They also have a wide temperature range, typically from -40°C to 120°C. EPDM is often more affordable than silicone, providing a cost-effective solution for many applications.

Disadvantages of EPDM Seal Rings

While EPDM seal rings are resistant to environmental factors, they may not perform well in applications involving petroleum-based fluids. They can swell and lose their sealing properties when exposed to oils. Additionally, EPDM may not have the same level of flexibility as silicone, which can impact its sealing effectiveness.

Comparing with Fluoroelastomer Seal Rings

Fluoroelastomers, such as Viton, are high-performance materials used for seal rings in demanding applications. They are known for their excellent chemical resistance and can withstand high temperatures, typically up to 200°C.

Advantages of Fluoroelastomer Seal Rings

Fluoroelastomer seal rings provide superior resistance to chemicals, making them ideal for harsh environments. They also have a wide temperature range and maintain their sealing properties under extreme conditions. This makes them suitable for aerospace and chemical processing applications.

Disadvantages of Fluoroelastomer Seal Rings

The primary disadvantage of fluoroelastomer seal rings is their cost. They are generally more expensive than silicone and other materials. Additionally, fluoroelastomers may not be as flexible as silicone, which can impact their performance in certain applications.

Conclusion

When comparing silicone seal rings with other materials, it is essential to consider the specific requirements of your application. Silicone seal rings offer excellent temperature resistance and durability but may not be suitable for petroleum-based fluids. Nitrile rubber is ideal for oil resistance but has a limited temperature range. EPDM is a cost-effective option for outdoor applications, while fluoroelastomers excel in harsh chemical environments. By understanding the advantages and disadvantages of each material, you can make an informed decision for your sealing needs